Resistance Welding

- TOP

- Resistance Welding

What is Resistance Welding ?

Resistance welding is used to join two metal objects.

In this process the objects to be welded are heated by resistance heat generated when the workpieces are sandwiched between welding electrodes that are passing current through them, The workpieces are pressed together between the electrodes and the metal is welded while pressure and current are applied.

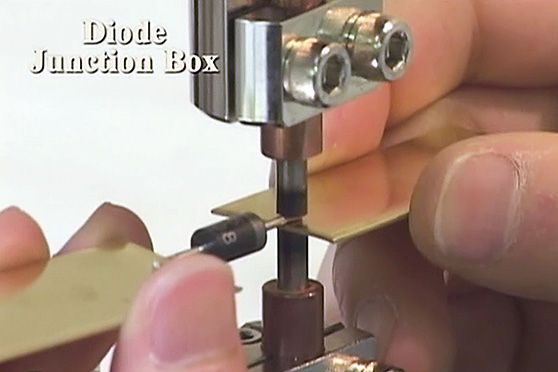

A resistance welding machine is composed of a welding power supply, weld head and electrode.

In the weld process the power supply supplies a welding current, the weld head exerts pressure on the materials to join and the electrode channels the welding current and pressure to the workpieces being welded.

We provide a variety of weld power supplies, weld heads and electrodes to meet a variety of client application requirements.

Features of Resistance Welding

Resistance welding is used for welding of two metal parts such as automotive electronics and other electronic components.

A variety of welding power supply types have been developed to allow targeted performance based on the specific application and desired joining outcome.

These different types include AC, capacitor discharge, inverter and transistor .

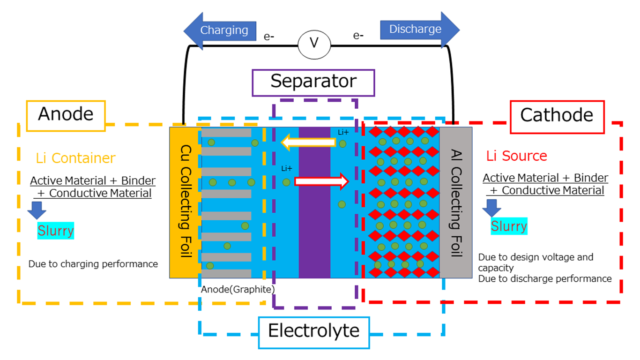

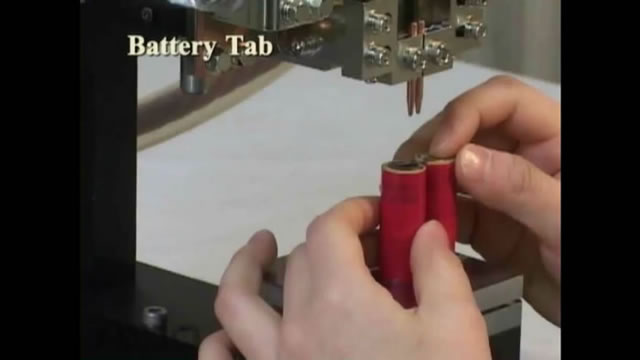

With the recent proliferous expansion of electric powered devices, the improvement of battery tab welding has become critical.

Application Examples:

- Fuse welding of wire strands in small motors used in automobiles and/or mobile phones

- Welding of insulated wires used in electronic components, such as resistor, capacitor, coil, transformer and IC card

- Metal to metal welds in solar batteries, lamps, connectors, switches, and battery tabs

- Welding of ECU’s, EFI’s, air bags and other automobile electronics

- Welding of various sensors, such as printed wiring board, gas, temperature, magnetic, pressure, strain, ultrasonic and acceleration

Resistance Welding Products

Resistance welding is used to join two metal objects.

In this process the objects to be welded are heated by resistance heat generated when the workpieces are sandwiched between welding electrodes that are passing current through them.

The workpieces are pressed together between the electrodes and the metal is welded while pressure and current are applied.

We provide a variety of weld power supplies and weld heads to support the multitude of customer applications.

Applications of Resistance Welding

Video and IM Micro Joining Examples :

Hot Bar Reflow Soldering

Hot Bar Reflow Soldering Ultrasonic Welding

Ultrasonic Welding Ultrasonic Metal Welding

Ultrasonic Metal Welding Parallel Seam

Parallel Seam  High Frequency Induction Heating

High Frequency Induction Heating