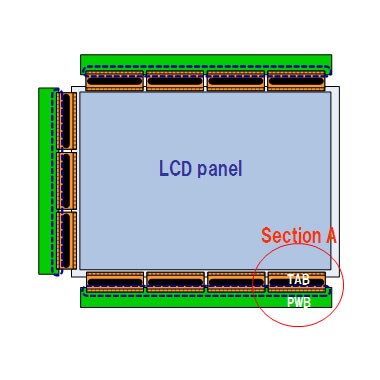

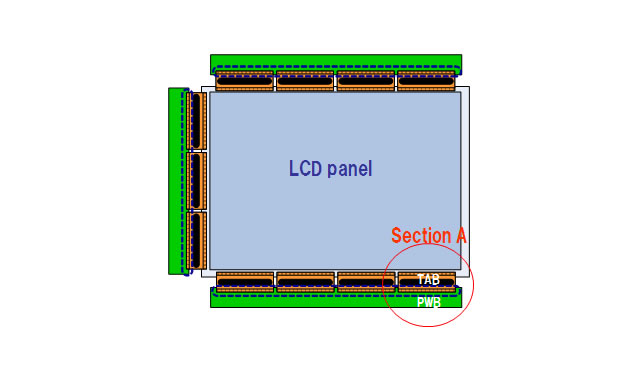

LCD module assembly

Features of Pulse Heat joining (Hot Bar Reflow Soldering)

When soldering or thermo-compression joining of flexible circuits, such as the TAB or the FPC, highly reliable joining can be realized without lifting up or misalignment by employing the pulse heat method where heating and cooling are conducted with the pressure being applied.

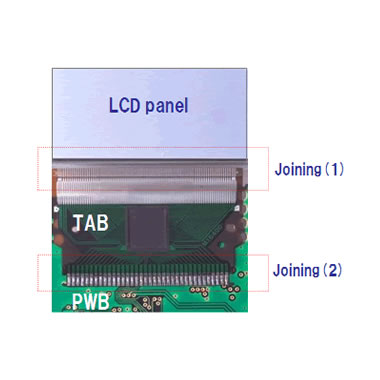

Joining(1) Joining of TAB on LCD panel

Welding copper alloys with high conductivity requires higher current than nickel.

The conventional "transistor-type" welder, which is assuming to weld nickel up to 0.2 mmt, does not have enough current and weld time. Therefore, resistance welder with high capacity for the battery tabs are required.

The highly reliable inverter type resistance welder NRW-IN400PA provide total solution for the challenges of the batterie tabs.

Joining(2) Joining of TAB and PWB (driver circuit)

TAB and PWB are connected by pulse heating via solder. Normally, solder is previously applied on the PWB side pattern.

Joining(3) Joining of PWB (driver circuit) and mother board

FFC (Flexible Flat Cable) is used for connection of LCD module and the main board (mother board).

Similar to the case of Joining(2), solder is previously applied on the PWB side pattern prior to the pulse heat connection.

Related video

Please be careful for the volume adjustment as this movie contains sound.

LCD module assembly

| Joining Method | Pulse Heat (Hot Bar) Reflow Soldering |

|---|---|

| Processing Method | Soldering, Thermo-compression Joining |

| End Products | LCD Module |

Sample test

We will be pleased to test your sample with our proposed joining method, and return it with a report.

Related Link

Applicable machine models

- General Purpose Type Pulse Heat Power Supply TCW-315

- High Power Type Pulse Heat Power Supply PHU-35

- Pulse Heat System Head NA-11 series, NA-15 series