Pioneer

in Micro Joining Industry

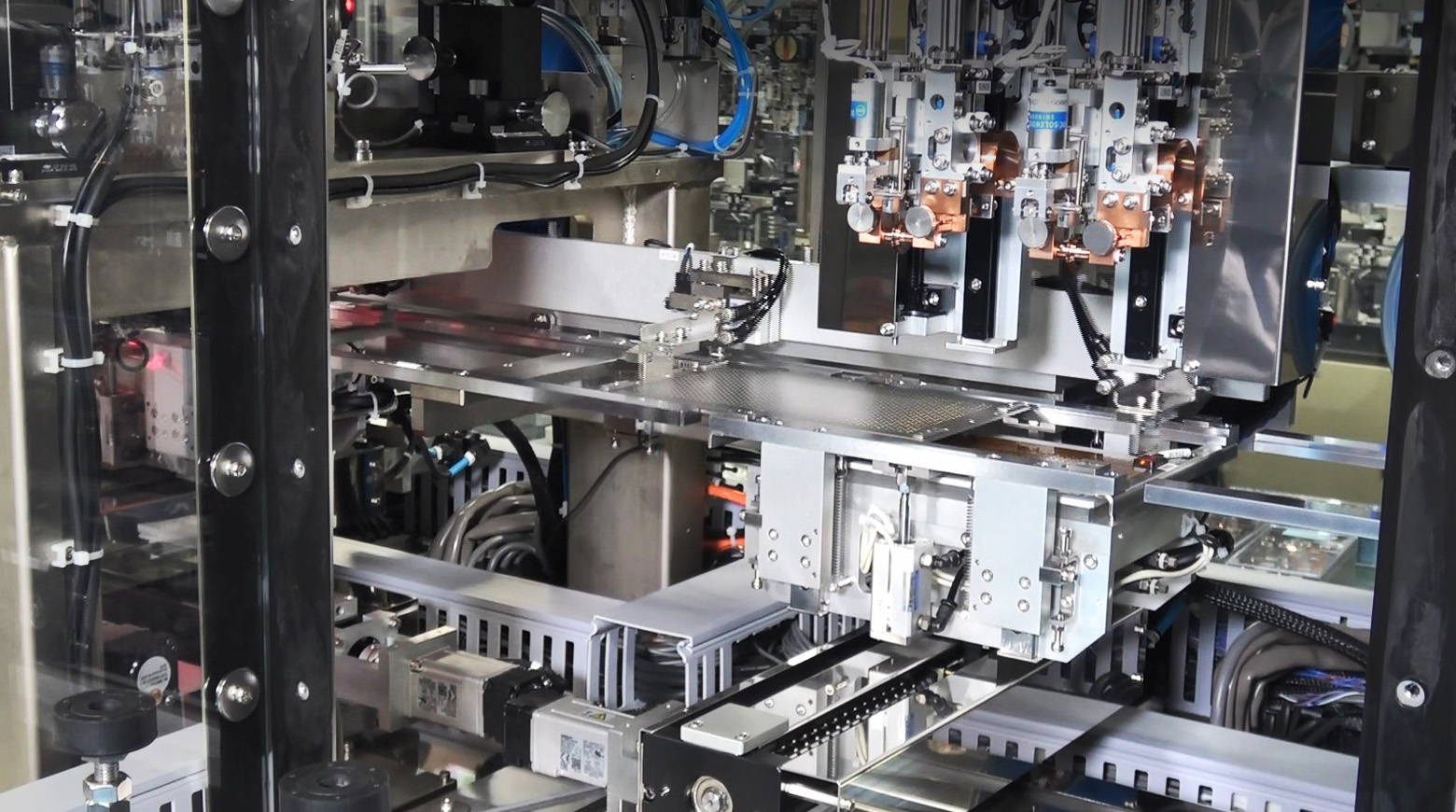

Micro joining technology of Avio is extensively used in the Manufacturing of electronic components and electronic devices.

Contact Us

Have any questions ?

Contact us for inquiry of products, sample tests, and technical consultation.