Parallel Seam Sealing

- TOP

- Parallel Seam Sealing

What is Parallel Seam Sealing ?

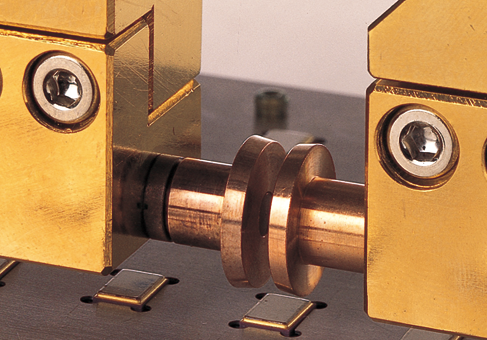

Parallel seam sealing is a method to hermetically seal lids to packages containing electronic components.

Using the principle of resistance welding, brazing materials such as nickel and gold-tin are melted and sealed through resistance heating.

Compared to other joining methods, parallel seam sealing has reduced thermal effect on the internal elements and higher joining strength.

Parallel Seam Sealer Features

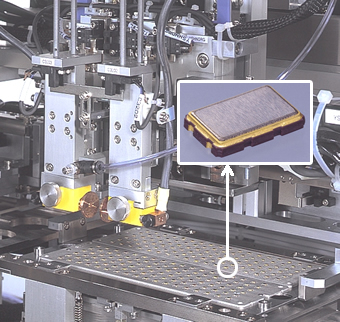

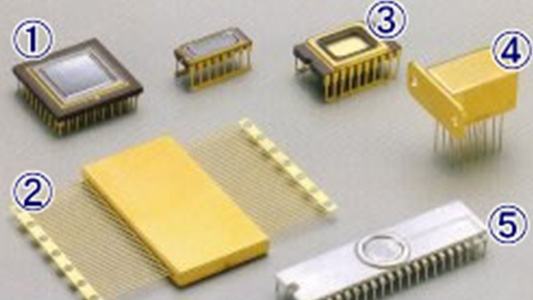

The main applications of Parallel Seam Sealing are quartz crystals used in communication equipment, acceleration sensors and MEMS.

Nippon Avionics' Parallel Seam Sealers are the industry leaders for sealing crystal oscillators.

The product line ranges from fully automated machines for use in mass production, to small-lot production and R&D applications.

Application examples:

- Crystal oscillators, SAW devices and vibration sensors

- Optical devices such as lasres, image and mirror sensors

- All-solid-state batteries, medical devices, etc.

Parallel Seam Sealing Products

Parallel Seam Sealer must seal packages in the vacuum or nitrogen atmosphere, depending on the device to be sealed.

Various models are available, from high-speed types with a machine tact time of 0.8 seconds to the type capable of sealing packages of 150 mm in size.

Parallel Seam Sealing Applications

Video and IM Micro Joining Examples

Hot Bar Reflow Soldering

Hot Bar Reflow Soldering Ultrasonic Welding

Ultrasonic Welding Ultrasonic Metal Welding

Ultrasonic Metal Welding High Frequency Induction Heating

High Frequency Induction Heating