Principle of Pulse Heat (Hot Bar) Reflow Soldering

- TOP

- Pulse Heat (Hot Bar) Reflow Soldering

- Principle of Pulse Heat (Hot Bar) Reflow Soldering

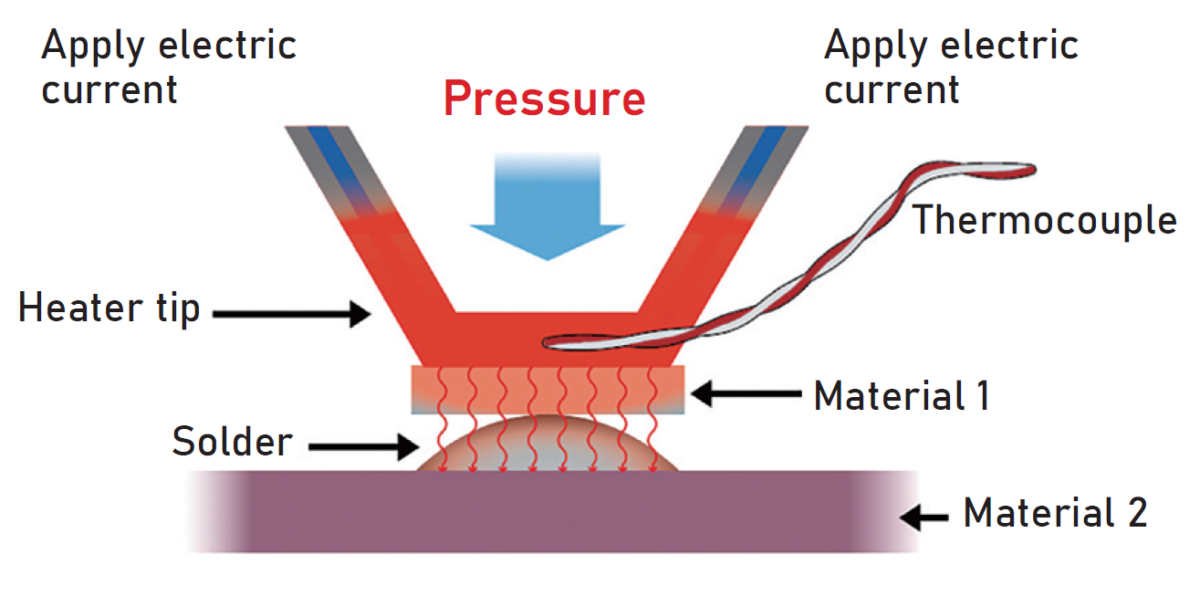

Pulse Heat is an instantaneous heating method of hot bar reflow soldering, which can make instantaneously soldering, thermocompression bonding, and resin welding by heat and pressure using resistance heat generated by applying electric current to a metal heating element called the heater chip/heater tool.

This is an original method unique of Nippon Avionics.

Basic process flow of Pulse Heat (Hot Bar) Reflow

- Press the heater tip/heater tool (Fig. 1) against the target work to pressurize

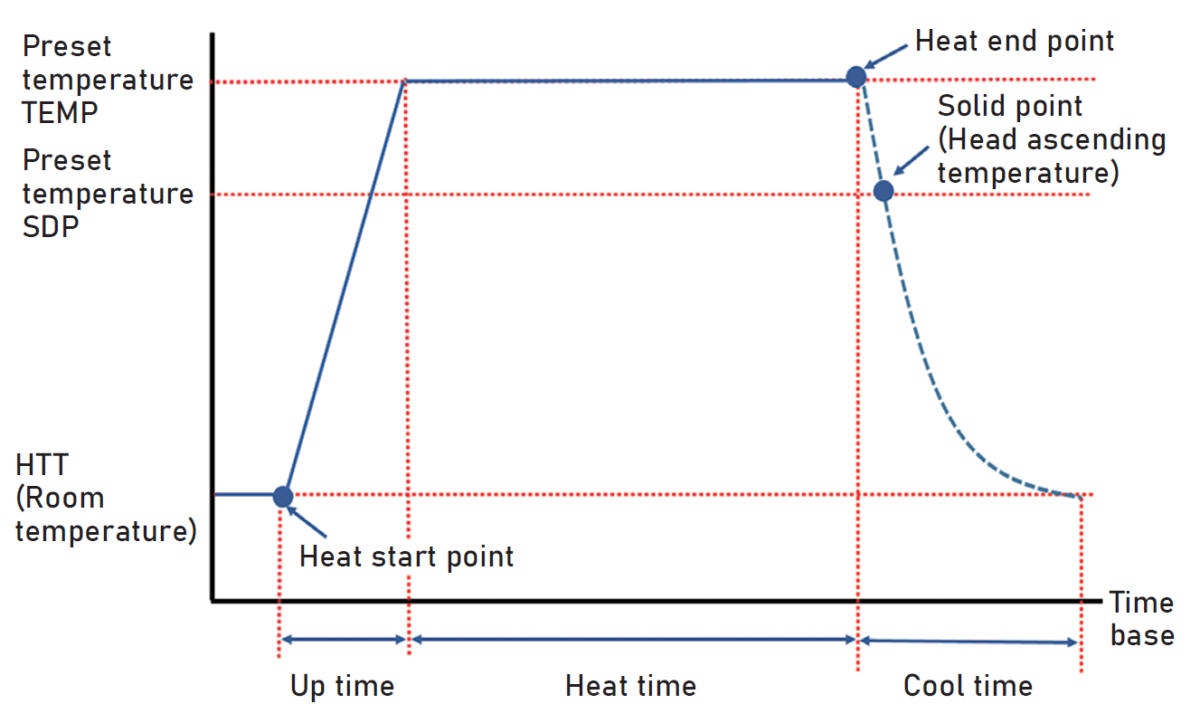

- Apply electric current to the heater tip/heater tool to raise the temperature from room temperature to preset temperature while pressurizing

- Hold pressure and heat for the set time

- When the set time is over, the welding is stopped, and when the temperature reaches to the preset cool temperature, the pressure is released

- The heater tip/heater tool return to room temperature (Fig. 2)

Basic Configuration of Pulse Heat (Hot Bar) Reflow Solderingart

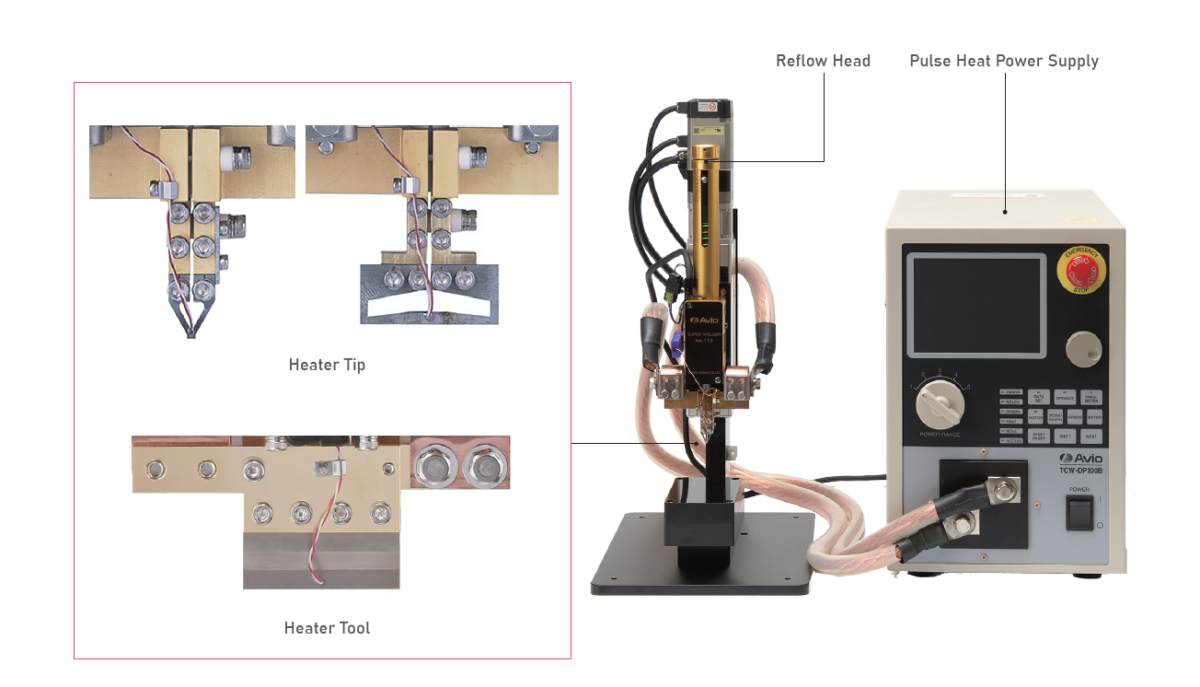

Pulse Heat (Hot Bar) unit consists of a reflow head to press the work for applying pressure, and a pulse heat power supply to apply electric current.

- Pulse Heat Power Supply: Electric current is flown to the heater tip or the heater tool.

- Reflow Head: The object to be joined is held down and a force is applied. The applied force is adjusted by a spring.

- Heater Tip & Heater Tool: This is the part which becomes hot by resistance heating.

- The one with a relatively small area is called “ heater tip” and a larger area is called “heater tool”.

* In addition to the above, we have various monitors which measure applied pressure

Features of Pulse Heat (Hot Bar) Reflow Soldering Units

The temperature control feeds back the temperature of the heater tip/heater tool and accurately reproduces the set temperature profile.

- The temperature rises quickly, and the temperature reproducibility is good.

- Temperature profiles such as pre/main heat can be easily realized.

- Due to local heating, the heat effect to the surroundings is small.

- Since it is cooled while being pressed down, there is no unconnected due to floating.

- It does not depend on skill level of the worker.

Movie Introducing the Principle of Pulse Heat (Hot Bar) Reflow Unit

Please be careful about the volume adjustment as this movie contains sound.

Resistance Welding

Resistance Welding Ultrasonic Welding

Ultrasonic Welding Ultrasonic Metal Welding

Ultrasonic Metal Welding Parallel Seam

Parallel Seam  High Frequency Induction Heating

High Frequency Induction Heating