Products

- TOP

- Products

Products Line up

-

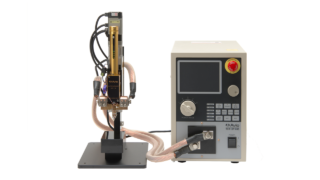

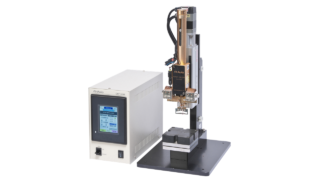

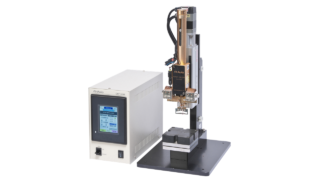

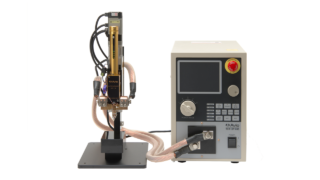

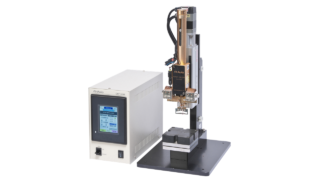

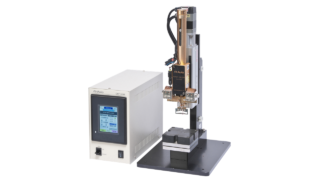

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

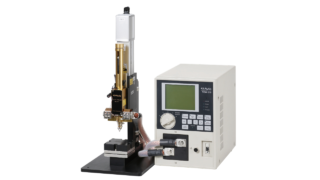

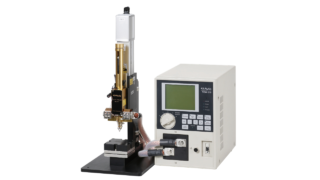

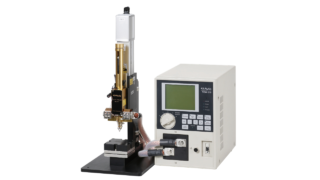

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

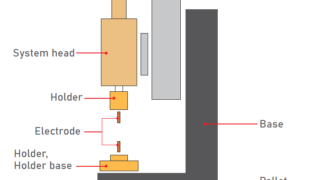

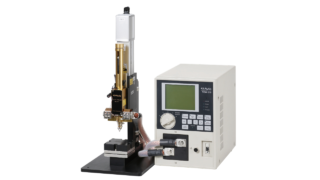

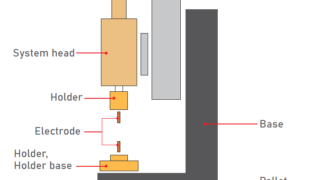

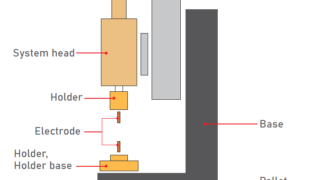

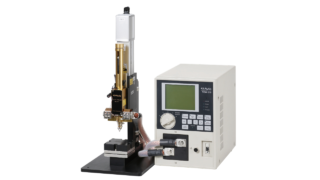

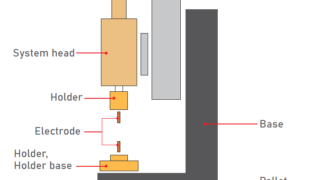

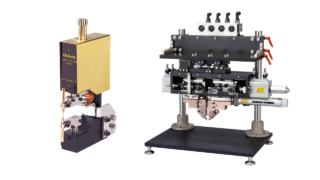

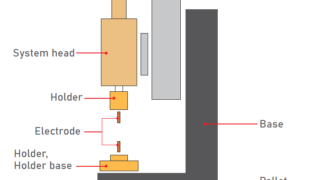

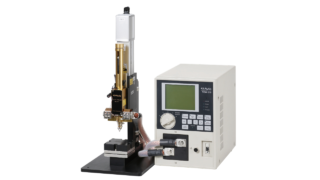

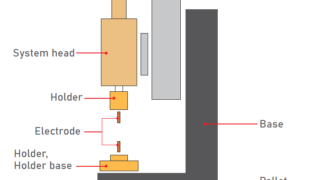

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

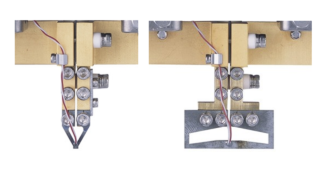

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

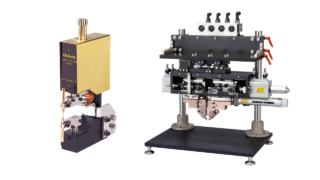

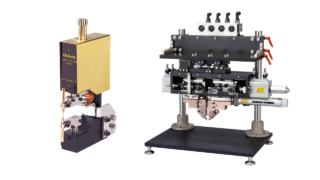

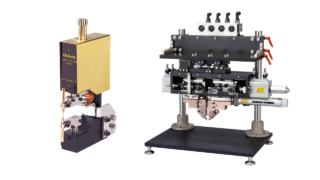

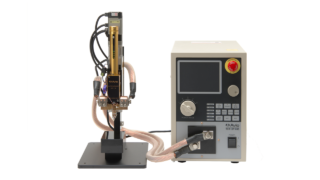

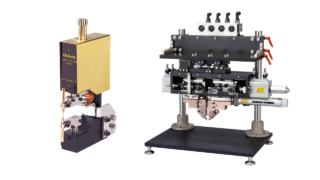

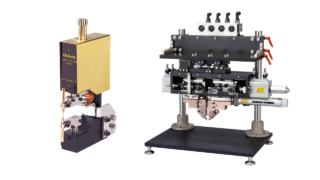

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

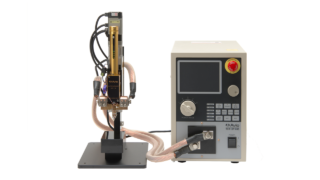

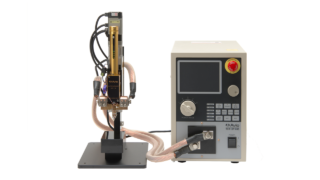

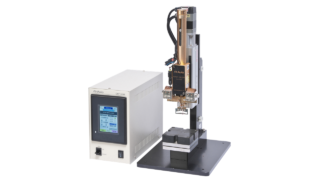

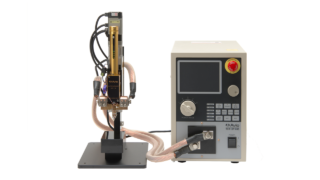

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

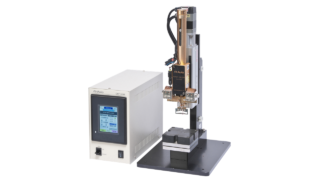

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

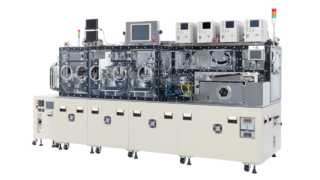

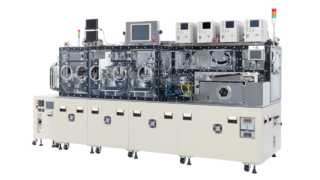

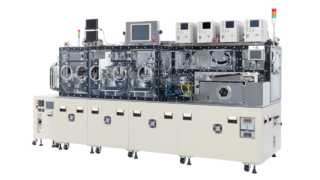

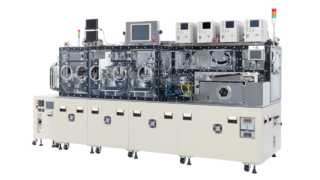

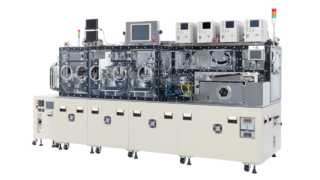

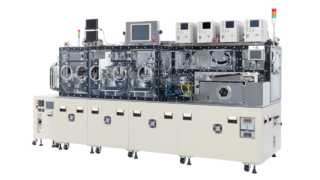

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

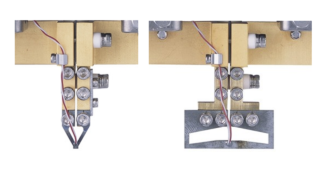

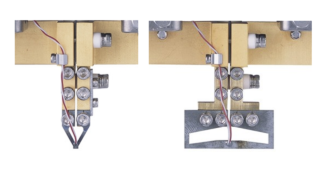

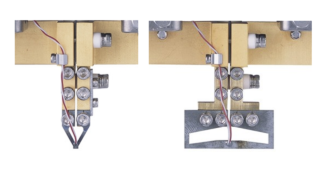

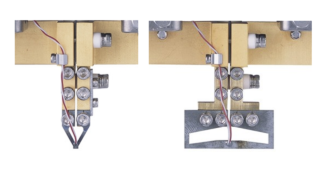

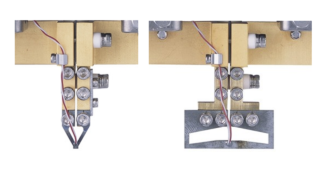

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.

-

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.

-

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.

-

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.

-

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.

-

Pulse Heat (Hot Bar) Displacement Type TCW-DP100

TCW-DP100B Concurrency Control of Temperature and Displacement

-

Resistance Welder High-reliability Inverter-type NRW-IN900P

This model is a large capacity type with 8-phase pulsation mode and maximum current of 32,000A.

-

Pulse Heat (Hot Bar) Soldering Machine General Purpose Type TCW-315

Most suitable for reflow soldering and Thermo-compression

-

Resistance Welder Inverter Model NRW-IN400PA

A model to be mounted on automated machines. Free-Selective frequency, 127-step freestyle welding profile

-

Resistance Welder Inverter Model NRW-IN8400A

This model features high-definition control and supports integration into automated weld system

-

Resistance Welder Inverter Model NRW-IN4200

The NRW-IN4200 inverter resistance welding model was designed to support precision weld of leads to terminal boards and leads to leads on electronic components.

-

Resistance Welder Transistor Models MCW-700 & MCW-750

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components

-

Resistance Welder DC Capacitor Model NRW-DC150A

This model includes a dual pulse function which is ideal for tab welding of batteries.

-

Drive Unit for Resistance Welder

Drive units for system heads. Electric slider (motor-driven ), pneumatic cylinder (air), and manual drive are available.

-

Welding System Head for Resistance Welding

Compact, high-performance system head suitable for precision resistance welding.

-

Accessories for Weld System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Resistance Welder

The NA-60A opposed type head with integrated drive unit, and the NA-184 horizontal pressure type head.

-

Hand Piece Type Head for Resistance Welder

Handpiece type heads for resistance welders.

-

Resistance Welding Monitor QC-450

Resistance Welding Monitor QC-450 is a highly functional welding monitor.

-

Pulse Heat (Hot Bar) Soldering Machine High Power Type PHU-35

High Power Type with separate power supply and transformer, suitable for mounting on automatic machines.

-

Reflow System Head

The reflow system head is for the Pulse Heat or the Hot Bar Soldering Machine to apply pressure and hold the object to be joined in soldering or heat caulking.

-

Ultrasonic Welding Machine SW-D Series

Ultrasonic Welding Machine SW-D series has 5 models of 20kHz~48.5kHz, 600W/900W with various control mode and monitoring function, which is applicable to wide variety of work.

-

Ultrasonic Handheld Welder HW-D Series

Ultrasonic Handheld Welder HW-D series can be incorporated into an automatic welding system as well. High power output model of 60KHz is included in the series.

-

Ultrasonic Welding Machine W3000 Series

Ultrasonic Welding Machine W3000 series covers a desk top model for easy operation and a model for incorporation into an automatic welding system.

-

Ultrasonic Cutter

Ultrasonic vibration is applied to the blade for smooth cutting of resins, fibers, and even rubber.

-

Ultrasonic Hon & Anvil

An ultrasonic horn is a resonator, with half the waveform being the basic unit, which relays the vibration energy efficiently

-

High frequency induction heating machine UI Series

A compact air-cooled high-frequency induction heating equipment that uses electromagnetic induction to self-heat metal nuts and bolt parts in a non-contact manner and press-fits them into resin molded products.

-

In N2 gas Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Parallel Seam Sealer with automatic lid placement

The Parallel Seam Sealer with automatic lid placement.It can be used for a wide variety of packages, from crystal devices to large optical devices.

-

In Vacuum Type Semi-Automatic Parallel Seam Sealer

It is a semi-automatic seam sealing equipment that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

In N2 gas Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in N2 atmosphere.

-

Automatic Lid Placement system

Automatic lid placement system is an equipment which automatically places lid such as crystal & SAW device, optical device, sensor, MEMS, etc.

-

In Vacuum Type Full Automatic Parallel Seam Sealer

It is a fully automatic seam sealing system that hermetically seals packages such as crystal & SAW devices, optical devices, sensors, and MEMS in vacuum.

-

Drive Unit for Pulse Heat (Hot Bar) soldering machine

Drive units for hot bar soldering machine system heads. Electric slider (motor-driven), pneumatic cylinder (air), and manual drive are available.

-

Accessories for Reflow System Head

Accessories for use with system heads and drive units.

-

Head with Integrated Drive for Pulse Heat (Hot Bar) Soldering Machine

NA-66 Reflow Head for the pulse heat or the Hot Bar Soldering Machine is an air-driven type head.

-

Force Monitor QC-100A

Force monitor QC-100A monitors weld head pressurization in real time. Force sensor for equipment integration is also available.

-

Heater Tip&Heater Tool for Pulse Heat (Hot Bar) Soldering Machine

Various Standard Type is Prepared!

-

Printed Wiring Board (PWB) Repairing Equipment

Equipment for pattern repair of printed wiring boards using the MCW-700 transistor type resistance welder

-

Digital Force Indicator FG-500

FG-500 is a portable digital pressure indicator. It is the successor to FG-400. Data management software for PCs is provided free of charge.

-

Welding Electrode&Resistance Weldability

Weldability and physical characteristic of each welding material and guideline for the electrode material selection are introduced.